Reason #1 - Excess water in the mix

Know the allowable water for the mix the contractor is pouring- or be very sure you have chosen a reputable contractor who will make sure the proper mix is poured. It is more expensive to do it right- it simply takes more manpower to pour stiffer mixes

.

Reason #2 - Rapid Drying of the concrete

Why cure concrete. Curing serves two main purposes.

- It retains moisture in the slab so that the concrete continues to gain strength

- It delays drying shrinkage until the concrete is strong enough to resist shrinkage cracking.

How to cure concrete.

- Water cure:The concrete is flooded, ponded, or mist sprayed. This is the most effective curing method for preventing mix water evaporation. Make sure you allow proper time for water curing.

- Water retaining methods:Use coverings such as sand, canvas, burlap, or straw that are kept continuously wet. The material used must be kept damp during the curing period.

- Waterproof paper or plastic film seal:Are applied as soon as the concrete is hard enough to resist surface damage. Plastic films may cause discoloration of the concrete-do not apply to concrete where appearance is important.

- Chemical Membranes:The chemical application should be made as soon as the concrete is finished. Note that curing compounds can effect adherence of resilient flooring, your flooring contractor and/or chemical membrane manufacturer should be consulted.

.

Reason #3- Improper strength concrete poured on the job

Reason #4 - Lack of control joints.

Be Active in Deciding Where Control Joints Will Be Placed

Space joints properly. Space joints (in feet) no more than 2-3 times the slab thickness (in inches). A 4" slab should have joints 8-12 feet apart.

Cut joints deep enough. Cut joints 25% of the depth of the slab. A 4" thick slab should have joints 1" deep.

How to cut joints. Grooving tools cut joints in fresh concrete. Saw cutting cuts joints as soon as the concrete is hard enough that the edges abutting the cut don't chip from the saw blade.

Cutting joints soon enough. In hot weather, concrete might crack if joints are not cut within 6-12 hours after finishing concrete. In this condition, if you don't want to use a grooving tool to cut joints, there are early-entry dry-cut lightweight saws that can be used almost immediately after finishing. These saws cut 1" to 3" deep, depending on the model.

Place joints under walls or under carpet areas.Under walls they won't be seen. Under carpet areas the joints won't have a chance to telegraph through vinyl areas.

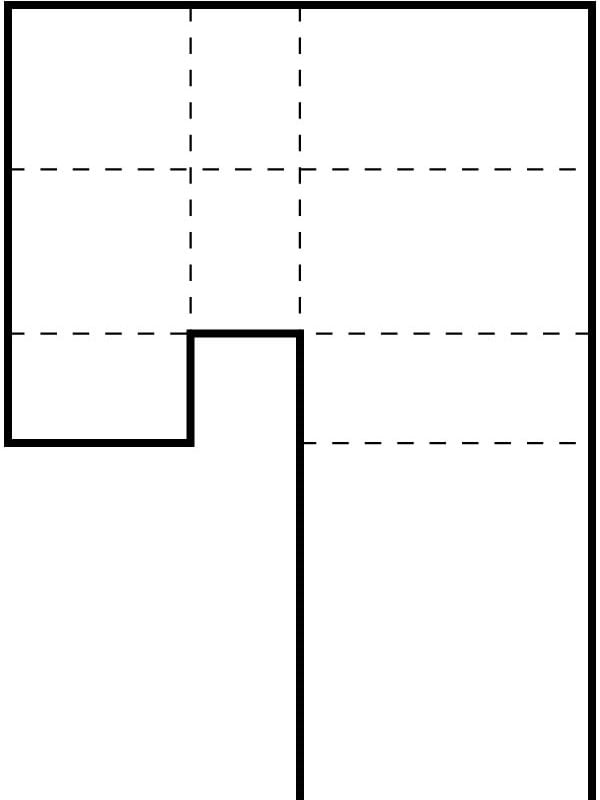

Avoid re-entrant corners. Planning the joint pattern can sometimes eliminate re-entrant corners.

Most plans don't have joint spacing marked on them. So don't leave this important part of concrete construction to chance.

Jointing is often not taken seriously enoughand the "sawcutter" comes to your job and puts the cuts where he feels they belong or where it is convenient for him.

Be active in deciding where control joints will be placed!

Other reasons:

Make Sure The Subgrade is Compacted

If these excavations are not compacted when backfilled, this loose soil will settle over time leaving the concrete over that area with no earth under it. This becomes a prime place for concrete to settle. Since the soil next to these excavations is native soil, the uncompacted trench can literally become a thoroughfare for water.

Most rental yards have compacting equipment and it is worth the investment to use it. Learn how to compact soil before pouring concrete.

Excavations from the house to the street for utilities should also be backfilled and compacted in the same manner so areas under the driveway concrete don't sink. Uncompacted areas under lawns can be identified by areas of sunken grass-so it is good idea to compact trenches even under areas not receiving concrete.

.jpg)